Detail

Wire rod lathes and milling machines are particularly suitable for industries that require cylindrical parts, precision hardware parts, mechanical parts, automotive parts, electronic components, and more. If you are looking for a way to perform precision machining on different materials (such as steel, stainless steel, copper, aluminum, etc.), this service can effectively enhance process efficiency and product consistency.

What is wire rod lathe machining?

- Wire rod lathe machining involves fixing cylindrical raw materials on the machine, with the workpiece rotating at high speed while the tool remains fixed, performing operations such as outer diameter cutting, grooving, and tapping. Common lathe processing sizes range: outer diameter Ø 4 ~ Ø 65 mm

What are the differences between milling and lathe machining?

- Milling machining involves fixing or moving the workpiece while the tool rotates at high speed to perform flat cutting or grooving. Lathe machining primarily revolves around the rotation of the workpiece, and both can be used in combination according to product requirements.

What steps are included in the machining process?

- Material selection and pretreatment

- Lathe machining (outer diameter cutting, tapping, etc.)

- Milling machining (flat or groove machining as needed)

- 👉Surface treatment (such as nickel plating, polishing)

- Dimension and quality inspection

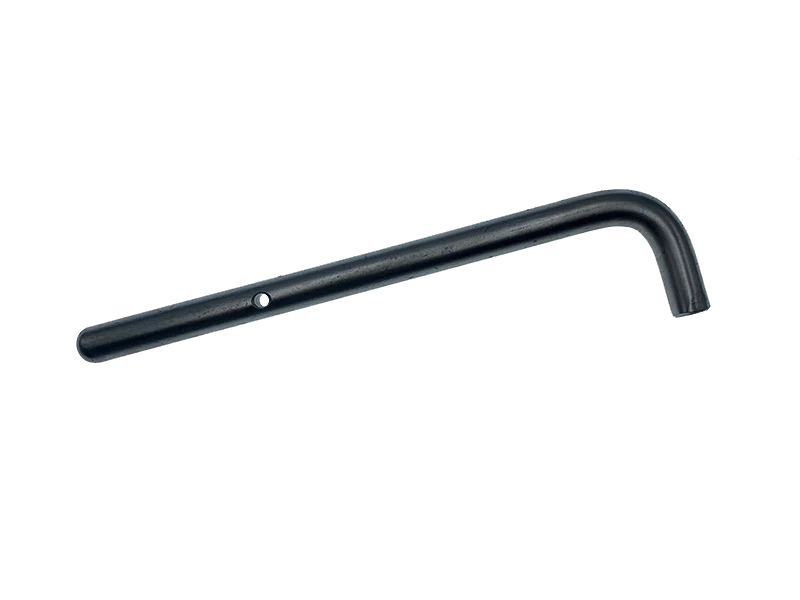

Commonly cnc turning and milling part manufacturing parts:

- Automotive parts (shafts, screws, sleeves, etc.)

- Electronic components (connectors, pins)

- Industrial machine components

- Metal accessories for home appliances and furniture

Sheng Ching has long-term cooperation with several professional precision turned parts manufacturers, and combines measuring equipment such as calipers, projectors, and surface roughness testers to ensure that every processed product meets drawing standards and precision requirements. We can provide small batch sampling and mass production services to help customers shorten development timelines and improve machining efficiency.

Choose Sheng Ching — a Taiwan processing integration expert focusing on wire rod lathe machining and milling integration. We accurately meet the machining needs of various materials such as steel, stainless steel, copper, and aluminum. In addition to cnc turning part manufacturing, whether it is automotive parts, electronic components, or industrial machine components, we can provide high-quality, stable delivery machining services according to customer needs.

In addition, Sheng Ching has rich experience in sheet metal stamping processing and assembly riveting, allowing for precise assembly and riveting of lathe-processed parts and sheet metal parts, completing part processing and assembly in one stop, saving customers procurement and manufacturing costs while ensuring product quality and consistency.

Contact Sheng Ching now to obtain exclusive custom quotes and technical support to help you enhance process efficiency and product competitiveness!

Product Inquiry

| Image | Product Name |

|---|---|

|

Wire Metal CNC Turning Part Manufacturing |