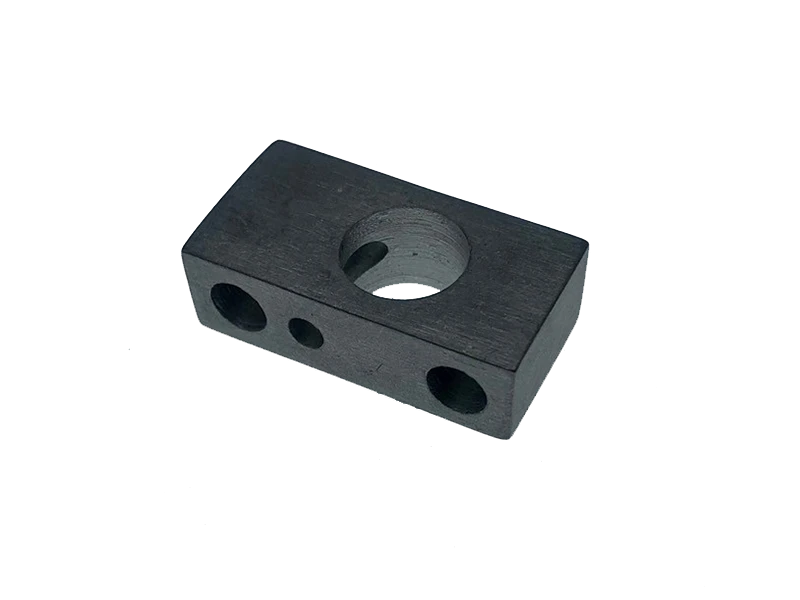

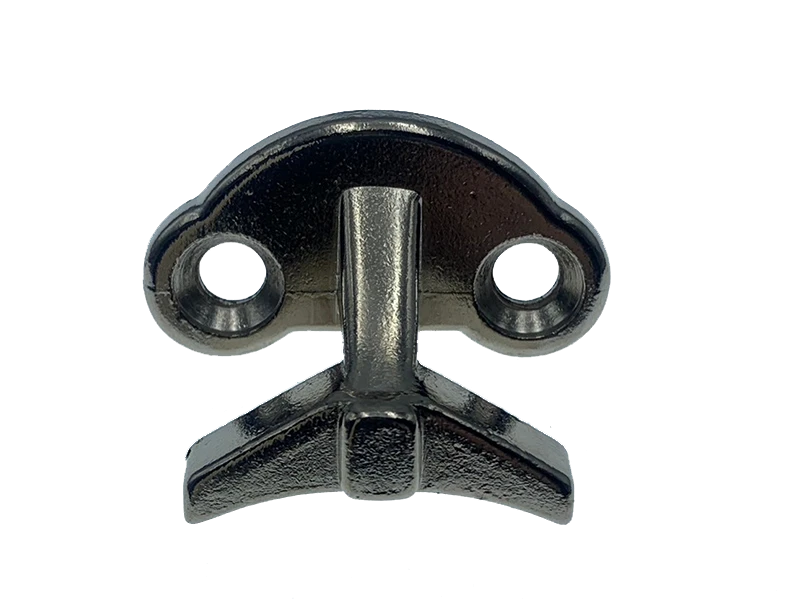

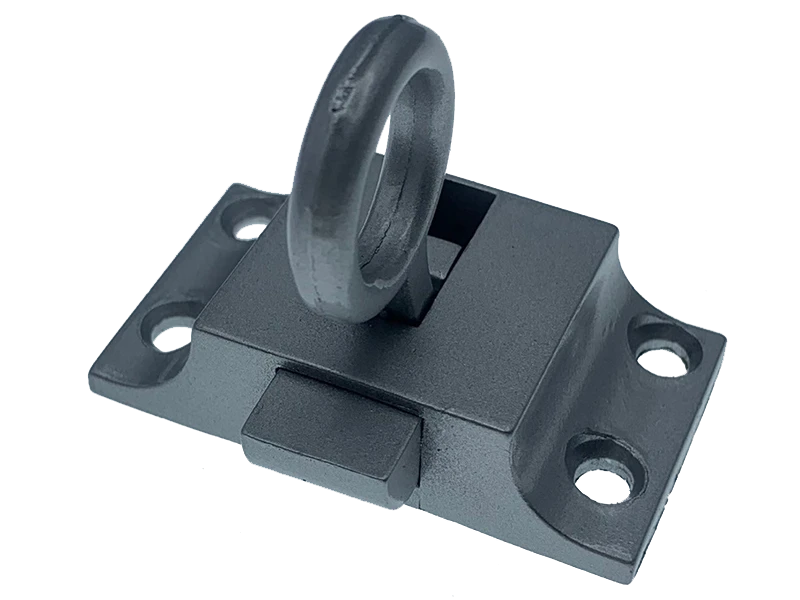

Pressure Die Casting & Assembly

Metal die casting is a common process used across many industries to produce precise metal parts, especially when products need high density and strong mechanical properties. Both zinc-alloy and aluminum-alloy Metal Die Casting can create dimensionally stable parts with smooth surfaces, often used in automotive components, electronic housings, and appliance hardware.

Sheng Ching — A Taiwan Pressure Die Casting Manufacturer for High-Precision Metal Parts

- We provide zinc and aluminum die-cast metal parts, along with various metal machining services. With multi-cavity mold design and automated production capabilities, we help customers boost efficiency and reduce material costs during mass production. Our services cover product consultation, sample development, and full-scale manufacturing support.

What products are suitable for die casting?

- Die casting is ideal for high-volume production and parts that require strong precision and durability, such as automotive parts, electronics housings, and furniture hardware.

What are the advantages of die casting?

- Able to form multiple parts in a single shot, increasing production efficiency.

- Smooth surface finish that reduces polishing or sandblasting work.

- Zinc and aluminum materials can be recycled, saving raw material costs and supporting sustainable manufacturing.

Surface Treatment

- After die-casting, various surface treatments are available to enhance appearance, durability, and corrosion resistance –👉 click here for full surface treatment details.