Product

Sheng Ching – Providing Custom Stamping Parts with Plate Thickness 0.30–10 mm, and also a CNC Parts Manufacturer with OD Range 2–140 mm.

Services at a Glance

- 👉Custom Stamping Parts: The press has a 👉maximum capacity of 1,000 tons, supporting progressive stamping, single-hit stamping, continuous stamping, and deep drawing (maximum drawing depth 150 mm), suitable for both mass production and small-batch pilot production can be combined with laser cutting and press brake processing.

- 👉CNC Machining: Turning and milling for OD 2–140 mm, tight-tolerance shafts, bushings, housings, and custom geometries; assembly-ready parts.

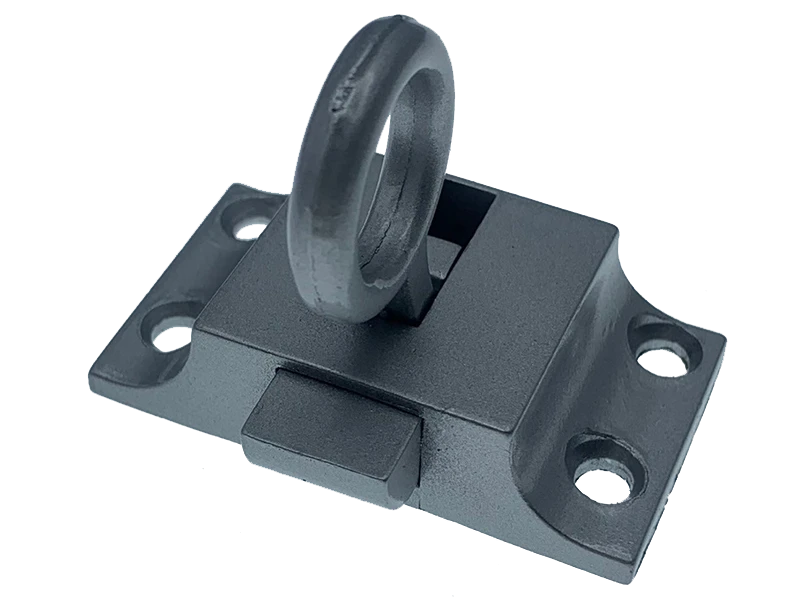

- 👉Pressure Die Casting: Aluminum and zinc components with dimensional stability; machining and thread finishing post-cast; assembly services.

- 👉Rubber & Plastic Molding: Injection and compression molding of elastomers and engineering plastics; overmolding and insert molding for multi‑material parts.

- 👉Surface Treatment: Electroplating, Anodizing, Painting, Blackening, Rust Prevention.

- Assembly & ODM/OEM: Mechanical assembly and part kit preparation, delivering complete ready-to-ship products.

Typical Use Cases

- Precision CNC shafts and housings for automation equipment.

- Stamped metal brackets and lamp base housings for electric car and motorcycle systems.

- Die-cast production for door latches and decorative hardware, with precision machining on assembly contact surfaces to ensure sealing and assembly accuracy.

- Secondary molded plastic parts with rubber or plastic overmolding for automotive and motorcycle components, as well as toolbox handles.

- Multi-Process Assemblies: We offer cross-process combinations including stamping, machining, die casting, and plastic parts. Components can be assembled, spot-welded, or jig-assisted according to product requirements to enhance manufacturing completeness.

What Buyers Often Ask

- Tolerances:

- Custom Stamping Parts: Repositioning accuracy up to hole diameter ±0.05–0.10 mm (depending on sheet thickness)

- CNC Machining: Dimensional and hole accuracy can be kept within ±0.05 mm.

- Materials: Carbon and stainless steels, aluminum, copper, brass, zinc alloys, engineering plastics, and elastomers specified by grade.

- Finishes: Anodize, powder coat, passivation, electroplating, e‑coat, black oxide, heat treat, shot‑peen; ROHS/REACH options available.

- Assembly: Hardware insertion, thread forming/tapping, bonding, rivet and screw assembly, functional checks per control plans.

- MOQ: 1,000 pieces, and inquiries below the MOQ are also welcome.

- Documentation: PPAP on request, material certs, dimensional reports, and traceability.

Why Choose Sheng Ching

- One-Stop Service: From mold making, stamping, turning/milling, die casting to surface treatment and assembly—coordinated through a single point of contact to reduce communication issues and lead time risks.

- We have an integrated stamping and assembly line that can combine sheet-metal parts with springs, rivets, rubber, plastics, and other components into finished products.

- High-Tonnage Capability: 1000-ton press handles thick plates and large parts, improving forming stability and yield.

- Industrial Hardware Expertise: Supports series production of equipment parts, mechanical components, and hardware accessories.