In-house equipment and technical capabilities

Core Processing Equipment

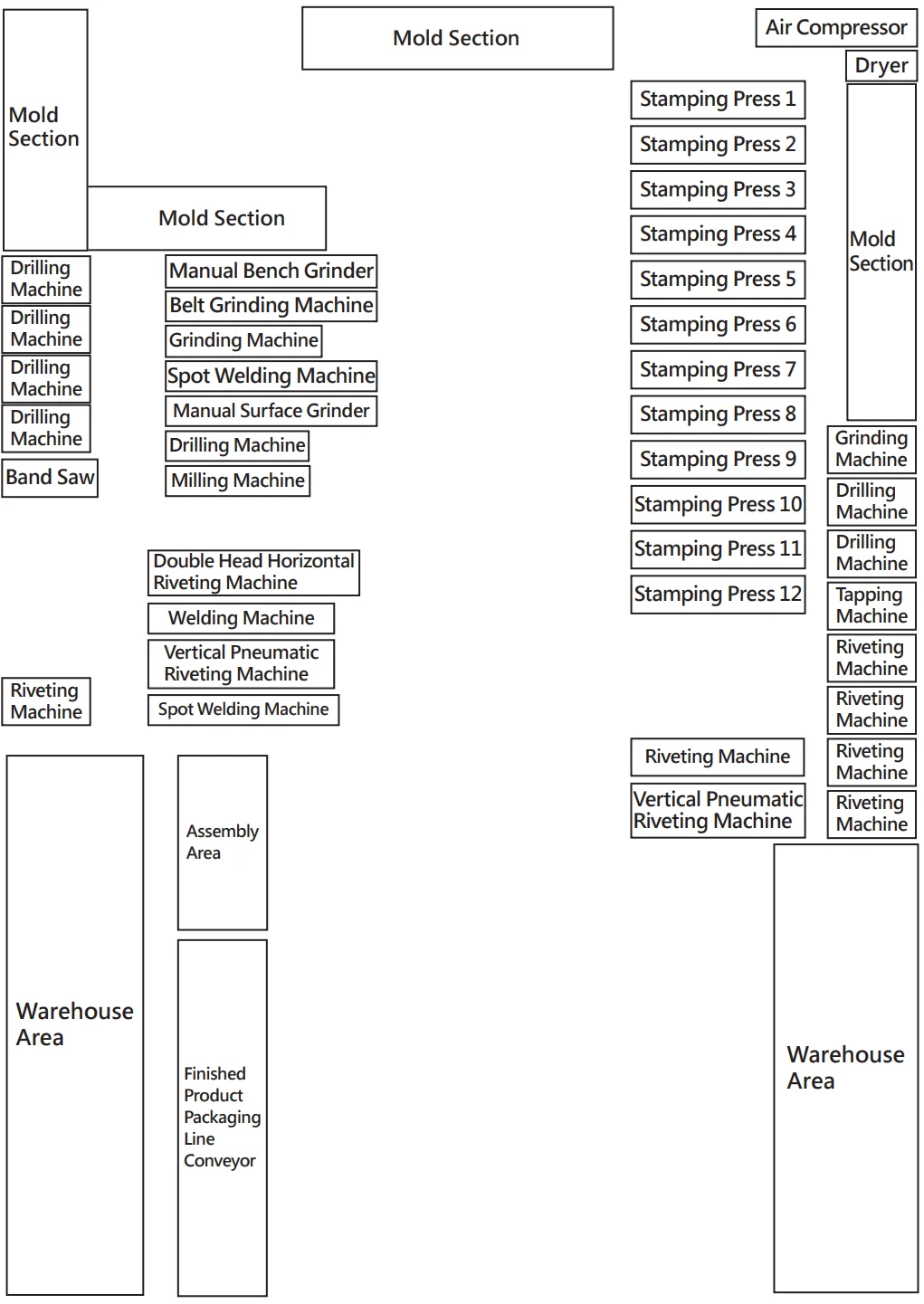

We have complete precision stamping and assembly capabilities, equipped with high-performance equipment and rigorous processes to meet the high standards of customer demands.

- Press: Equipped with 12 units high-rigidity presses, maximum pressure up to 500 tons, with a total height of 150 mm, capable of meeting deep drawing and complex forming requirements. Repositioning accuracy up to hole diameter ±0.05–0.10 mm (depending on sheet thickness) ensures stable and consistent hole diameters and external dimensions. Can process plate thicknesses ranging from 0.30 to 10 mm, and can be paired with multi-station molds to effectively improve efficiency and support diverse part structures.

- Drilling / Tapping Machine: Features automatic clamping fixtures and CNC control, with hole diameter accuracy stably controlled within ±0.05 mm.

- Grinding Machine: Equipped with surface grinding and external cylindrical grinding machines, capable of precision trimming of part edges or surfaces to ensure final dimensions.

- Spot Welding / CO₂ Welding Machine: Provides local structural reinforcement or pre-assembly welding, paired with positioning fixtures to control deformation.

- Other Auxiliary Equipment: Grinding machines are used for deburring and surface polishing; assembly lines and automatic feeding systems ensure overall process smoothness.

Quality Control and Measurement Equipment

Each part undergoes 100% inspection or sampling before shipment to ensure tolerances are within customer requirements.

- Coordinate Measuring Machine (CMM), measurement accuracy of ±0.005 mm

- High-precision shape gauges and measuring gauges

- Projectors and microscope inspection tools

- Automatic Optical Inspection (AOI) for surface defect inspection

Automation and Process Integration

High integration between equipment to reduce human error and enhance efficiency:

- Automatic feeding system connects press → drilling / tapping → assembly line

- Quick mold change platform, capable of switching molds in a short time, suitable for small batch custom production

- Full-process tracking system (MES / ERP integration) allows traceability of processing records for each part