Detail

Metal stamping processing is an indispensable method for many industries when producing metal parts, especially suitable for processes such as cutting, bending, and flattening wire. This type of wire stamping allows many components to achieve precise dimensions through one-time forming, reducing or even eliminating secondary processing. It not only enhances efficiency but also reduces costs and prevents cumulative tolerances.

Sheng Ching has over 30 years of experience in wire metal stamping processing, serving clients in the automotive, home appliance, construction, and industrial equipment fields. As a hardware stamping parts manufacturer, we are equipped with multiple high-speed stamping machines and automatic feeding systems, providing the most suitable processing solutions according to customer drawings and requirements, helping you efficiently complete production from design to finished product.

Processing Capabilities

- Processable wire diameter range: ø 4 ~ 15 mm

- Applicable materials: Iron, stainless steel, aluminum, and other metal wires

Standard Production Process (Iron)

- Stamping: Cutting, bending, or flattening the wire into the target shape

- Drilling / Tapping: Performing hole drilling and threading according to the drawing design

- Galvanizing: Surface treatment to enhance corrosion resistance and appearance quality 👉 click here for full surface treatment details

Main Application Areas

- Automotive parts (seat brackets, spring plates, automotive fasteners)

- Home appliance accessories (electrical connectors, structural fasteners)

- Construction hardware (wall hooks, hanging structural components)

- Industrial equipment components (clamps, transmission structures)

Quality and Trust

Sheng Ching is ISO 9001 certified and has established an internal inspection workflow with dimensional testing equipment. Every stage—from raw material acceptance to wire stamping and final shipment—is strictly controlled. We can also provide material certificates and outgoing inspection reports to ensure that products meet quality standards.

As a hardware stamping parts manufacturer with strong production capacity, we understand the importance of dimensional accuracy and consistent specifications for downstream assembly and functionality. If you are looking for a stable supplier with clear delivery schedules and solid technical support, Sheng Ching is a reliable choice.

Contact us now and let us help you build a more efficient and precise metal parts manufacturing process!

Product Inquiry

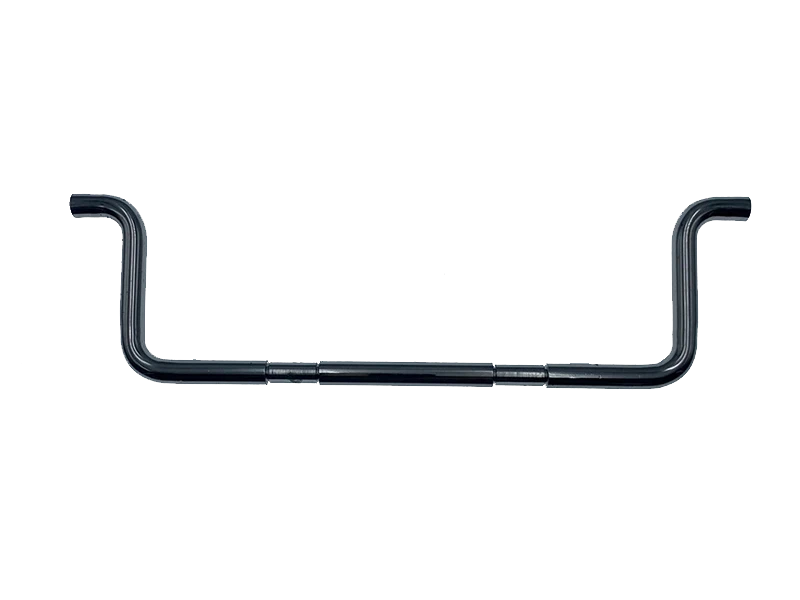

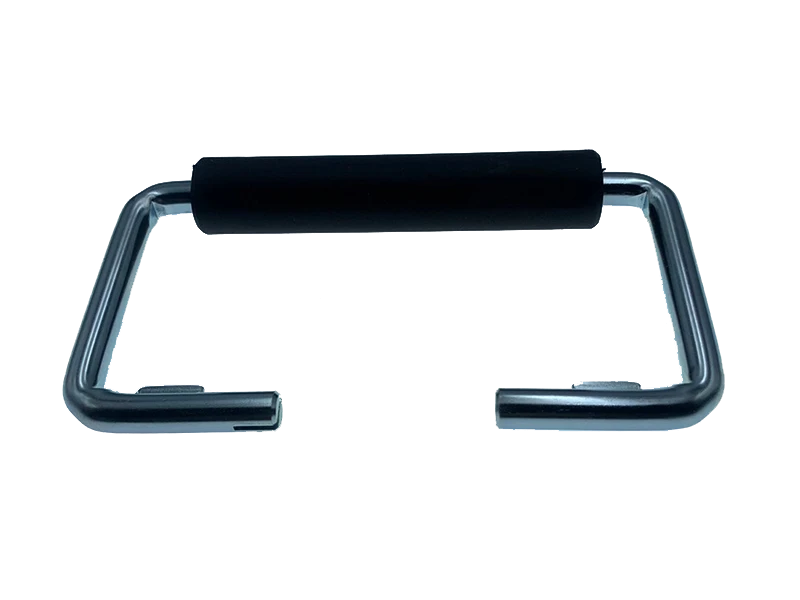

| Image | Product Name |

|---|---|

|

Metal Wire Stamping |